For efficient Piece Picking, SLC Picking and Pallet Picking

Robot integration as the future of intralogistics

Robot with precision to avoid errors

Increased efficiency through robot integration

Multi-task capability due to high adaptability

Efficient and multifunctional

Do you need robots for efficient intralogistics?

Integrating robots in intralogistics increases efficiency and precision, relieves employees of repetitive tasks and speeds up processes. Make sure to check out the benefits and application possibilities of robot integration, including Piece Picking, SLC Picking and Pallet Picking.

Customizable robot integrations from Peick FörderSysteme

Robot integration case studies

Introduction

In the world of intralogistics, where efficiency and productivity are of paramount importance, the integration of robots is increasingly becoming an indispensable solution. With the help of advanced robot technology, companies can optimize their warehouse and logistics processes to achieve competitive advantages. Learn about the possibilities robot integration in intralogistics offers for Piece Pickings, SLC Pickings and Pallet Pickings.

Integrating robots into intralogistics offers numerous benefits, including increased efficiency, precision and flexibility. Robots can perform repetitive tasks to reduce the workload for employees and minimize human error. They also enable faster task execution and continuous work performance, resulting in improved overall productivity.

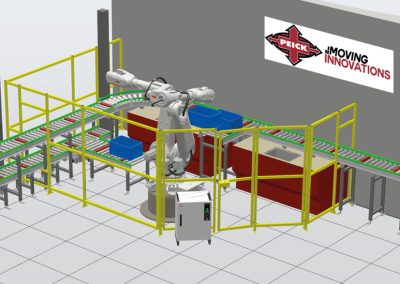

Piece-Picking

Piece picking is about removing individual items from the warehouse. This task requires precision and speed to minimize lead times. By integrating robots, companies can overcome this challenge. Robots with advanced gripping technology and vision systems can accurately identify individual parts, pick them up and transport them to the desired destination. This enables orders to be processed efficiently and errors to be reduced.

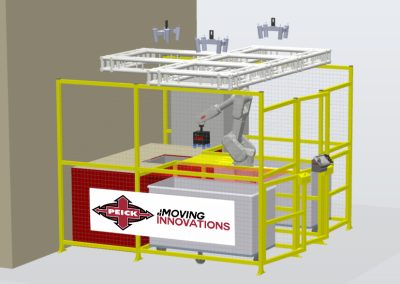

SLC-Picking

SLC (small load carriers) are common containers for transporting small parts in many industrial Picking SLC often requires complex handling steps, as parts can be close together. Through the integration of robots, companies can increase efficiency in the SLC-Picking increase considerably. Robotic arms with intelligent grippers can handle the KLTs precisely and quickly to ensure efficient and reliable picking.

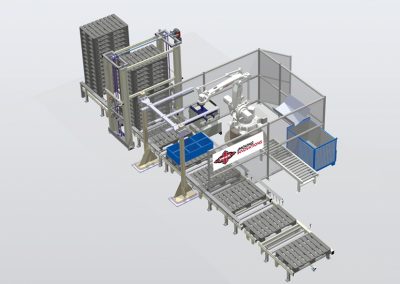

Pallet picking

Pallet picking byPallet picking requires greater load capacity and the ability to handle different items. Here, robots can be used with special grippers and forklifts to lift and transport pallets and place the desired items. This enables automated and efficient picking of large orders and helps optimize warehouse processes.Robot Integration Automate

Individual solutions

Robot integration in intralogistics offers companies the opportunity to optimize their warehouse and logistics processes and achieve competitive advantages. With robot solutions for Piece Picking, SLC Picking and Pallet Picking, companies can achieve higher efficiency, precision and flexibility. Customized solutions can meet individual requirements to ensure a smooth integration process and optimal performance.

Robot integration in intralogistics offers companies the opportunity to optimize their warehouse and logistics processes and achieve competitive advantages. With robot solutions for Piece Picking, SLC Picking and Pallet Picking, companies can achieve higher efficiency, precision and flexibility. Customized solutions can meet individual requirements to ensure a smooth integration process and optimal performance.

Customer service

Peick Contact

You have questions about our products and services and would like to learn more about Peick Fördersysteme GmbH? Then do not hesitate to contact us!

We look forward to your message.

+49 7144 91046 – 0

Certification

Our promise of quality

Values, such as “Made in Germany”, quality, and personal support to our customers are always our top priority. As a Swabian machine builder, we combine quality, tradition and innovative technologies.

Peick is certified due to DIN 9001:2015

We are here

Our sites

We are there for you.

You have questions about our products and services and would like to learn more about Peick Fördersysteme GmbH? Then do not hesitate to contact us!

We will be glad to hear from you.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationHeadquarter

Peick FörderSysteme GmbH

Zeppelinstraße 26

71672 Marbach am Neckar

Tel.: 0049 (0)7144 910460

Mail: info@peick-fs.de

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationConstruction | Project Management

Peick FörderSysteme GmbH

Am Halberg 13

66121 Saarbrücken

Tel.: 0049 (0)681 3875020

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationManufacturing | Construction | Project Management

PEICK Automation S.R.L.

Strada Dumitru Georgescu-Kiriac 11,

Cluj-Napoca 400394, Romania

Tel.: 0040 791 666 660